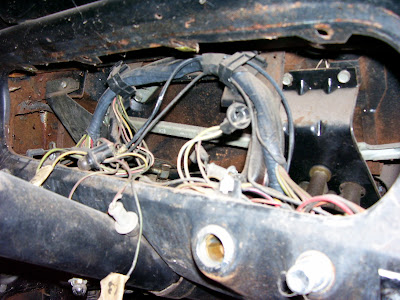

Did some odds & ends tonight,, started by finishing the removal of the harness running from the dash to the tail lights,, that was joy-joy fun. It'll be interesting when it's time to reinstall the new harness later on. Started removing some of the dash harness & where the bulkheads go though the firewall. There's sooo much to do, it's a bit overwhelming,,, hard to decide what to do next.

I decided to get some items out of my way,, so I started on the steering column. Removed the horn button, steering wheel nut,,, ran to the shop to get the puller,, and pop it was off. Like most old factory wheels,, this one is split in several locations,,, looks like another item to replace.

Note: If you're crazy enough to get into something like this project,, before you start,, go to the store and buy Several boxes of different size Zip-Lock baggies,,, a marker,, and some masking tape. Label and mark everything,,, there's like being organized,, it will definitely help you out,,, and you will lose a lot less parts. Also,, Take a bunch of pictures,, you can't have too many. Why do you think I'm posting all of these pics,,, not just to show you what I'm doing,, Mostly it's to help me remember where everything goes,, and how things are routed.

Here's what it looks like under the steering wheel,,, nice huh? I'm not sure if the turn signal switch works or not,,, not really important since I have a new one to install. There's a tapered ring that centers the center shaft with the bearing in the housing, you can kind of see it on the shaft(looks like a snap ring). It came out easy,, but it surprised me to see that it has an opening(split),,, since this is my first one of these,, I'm a bit curious if it's suppose to be like that,, or do I need a new one,, anyone know?

The 2 nuts on the right,,, and the bracket for the parking brake cable was next(angled cable,, 2 screws/bracket). When inside and removed the other 2 screws holding the PB handle assembly in place. It took me a few moments to figure out remove the cable from the handle,, it's pretty slick once you figure it out(my eye sight isn't very good up close & in dark places).

I then removed the brake pedal,, steering column seal(that was toast),, and a few other items. I get a kick out of the steering shaft,,, you can see that the column is removed,, but the steering shaft remains. It actually is attached inside of the steering box/sector and the other end hold the steering wheel on it,, pretty cool,,, definitely screws up any idea of installing a tilt wheel though,, unless you use a short shaft sector out of a slightly newer mustang. Maybe next time,,, since I just had the guys at Chockostang Classis Mustang Parts (in Illinois,, 217-882-2083) do a total rebuild on a spare sector I had,, boy it looks and feels nice!